Metrology

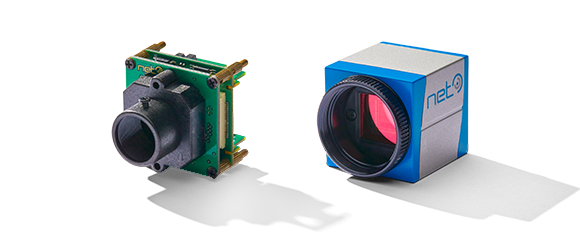

In the three-dimensional measuring of components, cameras are of central importance. We develop customized and flexible optical solutions for your production needs. Our camera technology stands for excellent linear grayscale distribution and high dynamic range. This enables the smallest deviations to be reliably detected, ensuring the highest degree of precision and dimensional accuracy.

3D contour measuring

3D contour measuring is an important means of ensuring the quality of, for example, grinding tools and crankshafts. If you’re searching for high-quality optics for your machines, our camera technologies are an innovative option. When it comes to machines with telecentric lenses, the fact that we place value on the best price/performance ratio when designing individual solutions gives you a real competitive advantage.

3D object measuring

Dentists, orthodontists and, of course, dental labs expect you, as manufacturers of medical equipment, to provide the highest degree of precision in the smallest of spaces. We have developed a small multi-camera system including optics that enables you to design your dental scanners for the 3D digitalization of tooth and denture models as compactly as possible. Integrated into small devices, its measurements are reliable and accurate. Added benefit: Our USB 3 cameras scan considerably faster than USB 2 even with parallel image acquisition.

3D position detection (coordinate measuring device)

3D coordinate measuring devices guarantee that the component exactly matches the CAD drawing. If you also carry out geometric measurements in the µm range and are dependent on a consistent range of focus with no geometric distortion, our open camera solutions featuring integrated image rectification and autofocus are a safe choice. These requirements have been implemented for Zeiss Industrial Metrology.

Tool inspection

If you are looking for cameras for non-contact geometric tool measuring in the µm range, NET is the right choice for you, particularly where the customized inline integration of lighting and optics in the smallest of spaces is concerned. What makes it special: Our compact all-in-one system features the appropriate telecentric lenses and compensates the lack of space for the PC. How you benefit: Our non-contact geometric measuring technique ensures the quality of your tools.

application

is not

included?