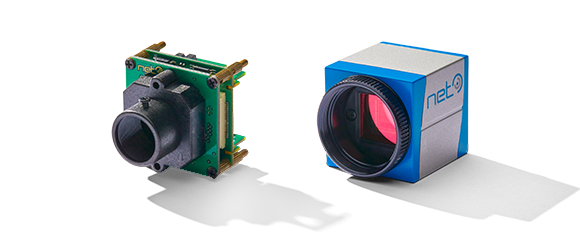

High-quality printing results require uninterrupted and error-free manufacturing processes. The immediate detection of quality defects is also crucial. Our camera technologies stand for high frame rates, accuracy of detail and high color dynamics. Our open camera concept allows individual image pre-processing using your own application-specific algorithms.

Endless material label inspection

Intelligent error detection and classification is just as important to you as it is to our customer Erhardt+Leimer? You want to equip your inspection systems with cameras that function equally as imagers and flash control systems for different types of lighting? Our cameras can do both – on the basis of on-time processing and signal transmission via an IP core developed by us, which is processed in the camera in real-time.

Flatbed printing control

We’ve developed a 3D solution that enables your printing system to receive the precise position data of large media, such as panels or boards, and position the print head automatically and flexibly. Cameras with integrated image processing features record and evaluate large volumes of data. How you benefit: Only the data necessary for position detection is transmitted to your printing system. This gives you greater flexibility and makes printing more precise.

Packaging label inspection

You inspect round objects such as tubes, cans or bottle caps during the packaging process? You have to be able to check labels and the quality of their coating quickly? Our open decentralized system uses your existing image processing software; control software can be ported. The Windows-based all-in-one vision system featuring a line sensor works with a line scan camera for on-the-spot image processing. The advantage for you: Machine control and ERP can be connected to it, meaning that there is no need for another PC.

Registration mark alignment

For the manufacturers of screen printing machines, we’ve solved the problem of space between the object and the template – with a compact USB camera. As the manufacturer you benefit from both the new machine and the retrofit. The best thing is that our cameras can be easily integrated into existing software architecture. USB cameras are the right choice when it comes to mastering the challenge of determining the position of the registration mark for the correct alignment of the printing machine and the PCB.

application

is not

included?