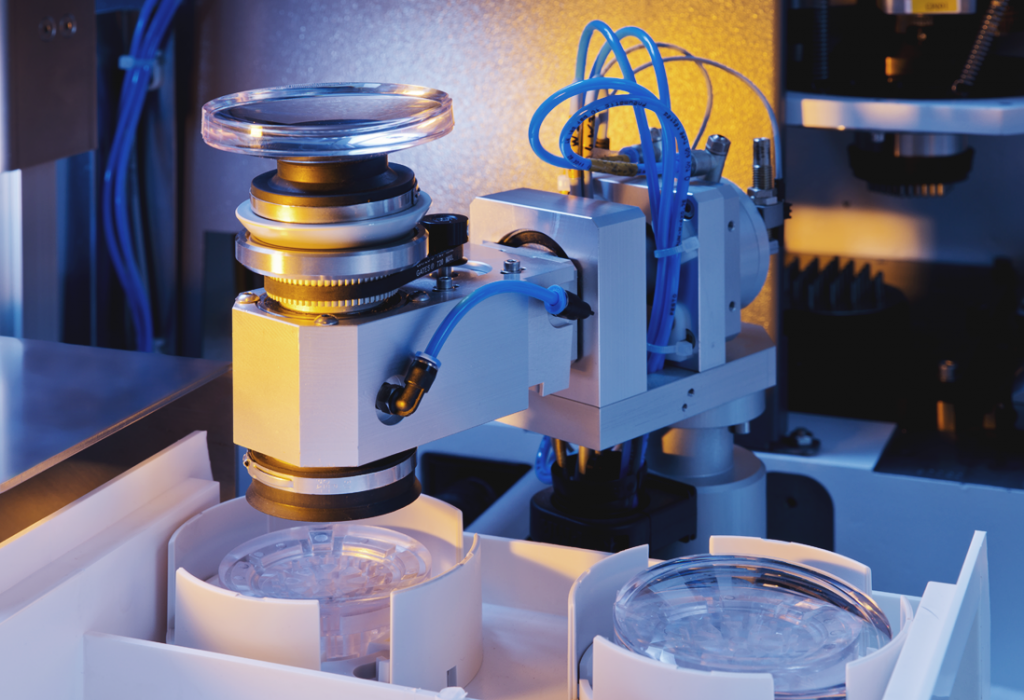

CNC-assisted automated solutions for the high-quality surfacing of optical lenses and glasses require the precise recognition of markings. Only with this can perfect alignment in the processing of plastic blocks be achieved. Satisloh, a global leader in machine manufacturing, trusts in NET’s compact USB 3.0 cameras combined with the right lighting and optics. A good choice for reliable 24/7 industrial use.

Application

Satisloh is a pioneer in the field of environmental-friendly, alloy-free spectacle lens production. The automated solutions are more efficient, longer-lasting and even safer for staff due to the absence of heavy metal pollution. Unlike the older, conventional processes, the spectacle lenses are blocked and prepared for further processing fully automatically. Organic block-pieces and UV-curable adhesive are used. The procedure is considerably faster than the old-fashioned manual production process.

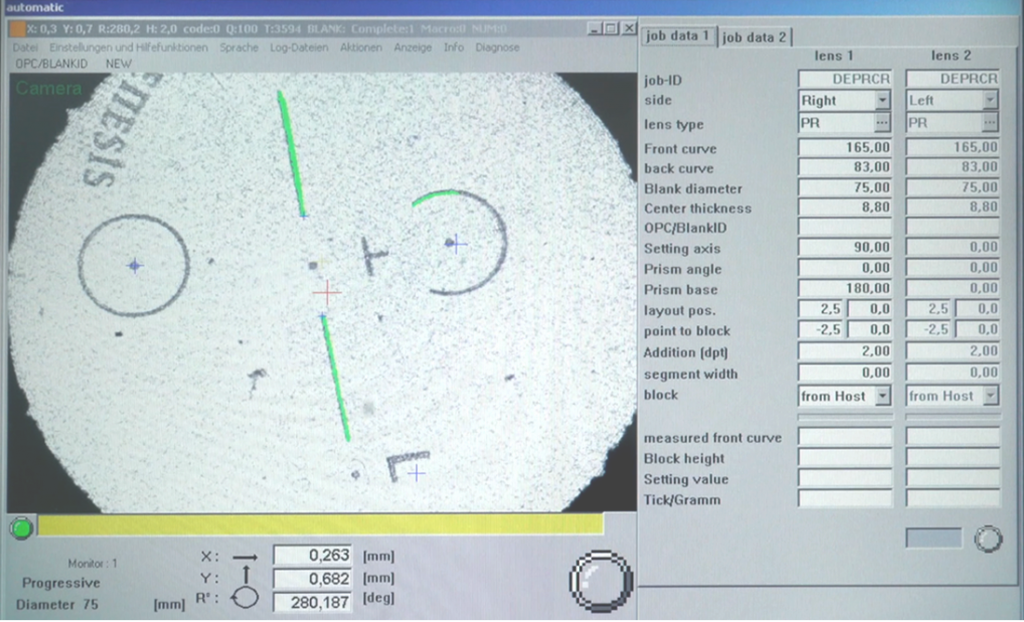

With multifocal lenses, the orientation of the lens plays a major role. Front-side progressive lenses have a free-form surface on the front of the blank. There are markings on this surface which have to be detected before the blank can be further processed. Satisloh has developed a software solution for this.

Challenge

The main aim was to optimize the vision system to support high-precision blocking and, at the same time, enable throughput increase. The necessary requirements for this are the perfect interaction of the image processing components and a high degree of reliability under industrial working conditions.

Solution

NET’s compact USB 3.0 cameras combined with the right lighting and optics result in a perfectly coordinated vision system, which produces precise measurements while maxing out the image processing speeds. The solution is designed for robust permanent use.