Line scan sensors offer unique advantages over area scan sensors, when it comes to inspection of moving objects. We would like to give you an overview of applications suitable for smart line scan cameras, and give guidance how to make optimal use of smart image processing systems.

Especially when inspecting continuous material, or moving objects, a continuous image acquisition without any gaps is much more efficient. Requirements like minimal detection lag, high resolution, reduction of distortion, zero pixel defects, or more simple lighting configurations clearly favor line scan sensors.

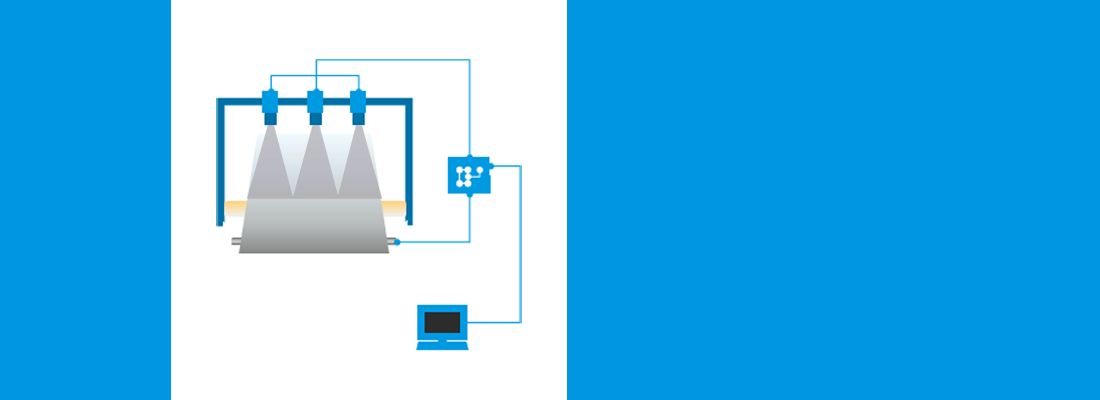

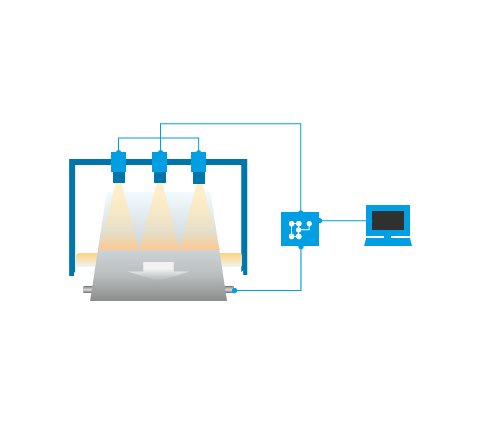

Web Inspection of Film and Glass Substrate

Inspection systems are commonly used in blown film and flat film extruders as well as in converting or coating lines.

Detection of various defects on continuous materials, like foil or film, require special lighting setups, which consist of multiple lights. Any combination of bright field, dark field, or even multispectral lighting may be required to detect all anomalies on the material. Since multiple light sources may eliminate each other, only one light source can be used per line.

In order to record every position on the surface with all different light sources, the line scan cameras used need to support fastest line rates with virtually no jitter.

CORSIGHT offers line scan sensors with line rates of up to 1 million per second and guarantees virtually jitter-free acquisition. Furthermore, CORSIGHT provides the right hardware to process the image data in real time, for example by calculating 2D filters on the fly in the camera’s FPGA, even before it is available to the CPU for evaluation.

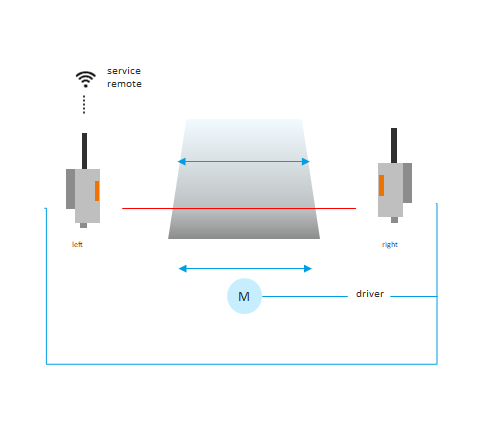

Position Measurement / Web Guiding

CORSIGHT line scan smart cameras detect the position of the web edges, and calculate the current position within a millisecond. The camera also registers the current position of the linear drive using the encoder signal connected to one of CORSIGHT’s digital I/O ports. The software solution running directly on CORSIGHT is now able to compare the web’s current position with the expected position, and controls the linear drive to compensate for the displacement. This implements a closed loop system to keep the web within tolerances.

A CORSIGHT all in one solution can be used for various applications, for example, if two or more layers need to be laminated. It is easy to detect the position of materials for the adjustment of cutting tools, or the position of the material itself in winding stations.

CORSIGHT features an Intel Atom E3940 CPU with Windows 10 IoT, or Linux as operating system. A large choice of area scan, high speed, and line scan sensors is available. Connectivity options include Gigabit Ethernet, USB, RS232, DisplayPort, Bluetooth, and even WiFi. CORSIGHT’s open platform allows to run various standard image processing libraries as well as customer specific algorithms. NET’s Open Camera Concept even allows customers to use resources like the onboard FPGA.

Advantages of Line Scan

- Resolution and Cost: In the above example, compared to a typical 16MP Global Shutter area scan camera, a 4K line scan camera might come at half the cost or even less.

- 100% Inspection: Unlike an area scan camera, special shuttering and image stitching techniques are not needed to obtain a continuous image of an object’s surface. There are no gaps, overlaps, or smears in the captured image.

- Lighting setup: As only the portion of the object covered by 1 line of pixels needs to be illuminated, it is much easier to achieve homogenous lighting than with an area scan camera.

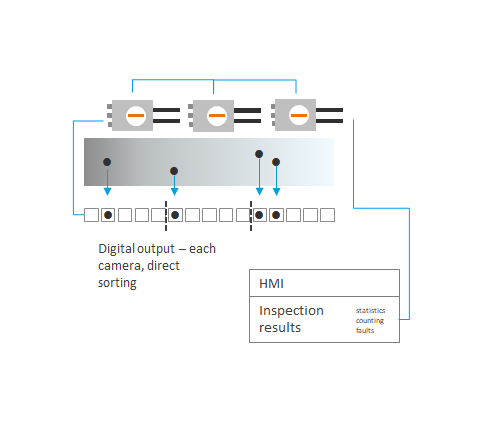

Sorting of fast moving and small Objects

NET offers CORSIGHT as a smart vision system with integrated line scan sensor (2 and 4 K) and line scan functionality in area scan sensors. NET`s 3iCube / iCube USB cameras and GigEPRO cameras offer line scan functionality with area scan sensors.

Sorting machines are used to automatically check dimensions and surface condition of bulk goods at highest speed. Every smart vision system is able to work autonomously in a certain range of the conveyor.

It then decides if an object is good or bad, directly controls the sorting mechanism in real time, and transmits statistical data to a central processing unit. Depending on the type of objects, a free fall setup instead of a conveyor may be realized even without knowledge of the current speed.

The compact all in one machine vision system CORSIGHT offers highest sorting efficiency right where it is needed, instead of the need to rely on complex interfaces like camera link, or 10 GigE. All smart processing resources, like CPU or FPGA, can be used in a custom application based on NET’s Open Camera Concept.

5 pros for Smart Line Scan vs. Smart Area Scan

- resolution higher resolutions achievable with 1k up to 4k

- speed up to 1 million lines per second

- components homogeneous illumination of an area vs. a small line illumination

- sensor size allows standard CCTV and C-mount lenses

- architecture built in FPGA:

> no external frame grabber / video output

> built in incremental encoder: no additional gearbox or trigger generator required